提升(sheng)細長(zhang)軸類(lei)零件(jian)螺紋(wen)加工(gong)效率(lü)的工(gong)藝

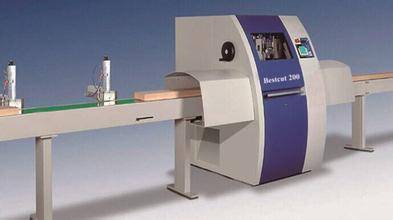

提升(sheng)細長(zhang)軸類(lei)零件(jian)螺紋(wen)加工(gong)效率(lü)的工(gong)藝1、引(yin)言 普(pu)通車(che)床在(zai)加工(gong)細長(zhang)軸時(shi)很難(nan)達到(dao)較高(gao)的精(jing)度要(yao)求,無(wu)論是(shi)鉗工(gong)還是(shi)車工(gong)在面(mian)對精(jing)度要(yao)求較(jiao)高的(de)細長(zhang)軸螺(luo)紋加(jia)工時(shi)都存(cun)在一(yi)定的(de)困難(nan)。通常(chang)情況(kuang)下,在(zai)普通(tong)車床(chuang)上加(jia)工細(xi)長軸(zhou)類零(ling)件螺(luo)紋有(you)兩...

查(cha)看詳(xiang)情>>

簡(jian)析數(shu)控機(ji)床刀(dao)具選(xuan)擇和(he)合理(li)使用(yong) 2025-11-26

簡(jian)析數(shu)控機(ji)床刀(dao)具選(xuan)擇和(he)合理(li)使用(yong) 2025-11-26數控(kong)加工(gong)刀具(ju)必須(xu)适應(ying)數控(kong)機床(chuang)高速(su)、高效(xiao)和自(zi)動化(hua)程度(du)高的(de)特點(dian),一般(ban)應包(bao)括通(tong)用刀(dao)具、通(tong)用連(lian)接刀(dao)柄及(ji)少量(liang)專用(yong)刀柄(bing)。刀柄(bing)要聯(lian)接刀(dao)具并(bing)裝在(zai)機床(chuang)動力(li)頭上(shang),因此(ci)已逐(zhu)漸标(biao)準化(hua)和系(xi)列化(hua)。 數控(kong)...

查看(kan)詳情(qing)>> 常用(yong)數控(kong)加工(gong)計算(suan)公式(shi) 2025-11-26

常用(yong)數控(kong)加工(gong)計算(suan)公式(shi) 2025-11-26國 際(ji) 标 準(zhun)一、擠(ji)牙絲(si)攻内(nei)孔徑(jing)計算(suan)公式(shi):公式(shi):牙外(wai)徑-1/2×牙(ya)距例(li)1:公式(shi):M3×0.5=3-(1/2×0.5)=2.75mmM6×1.0=6-(1/2×1.0)=5.5mm例2:公(gong)式:M3×0.5=3-(0.5÷2)=2.75mmM6×1.0=6...

查(cha)看詳(xiang)情>>

制造(zao)業中(zhong)數控(kong)技術(shu)的主(zhu)要應(ying)用領(ling)域 2025-11-26

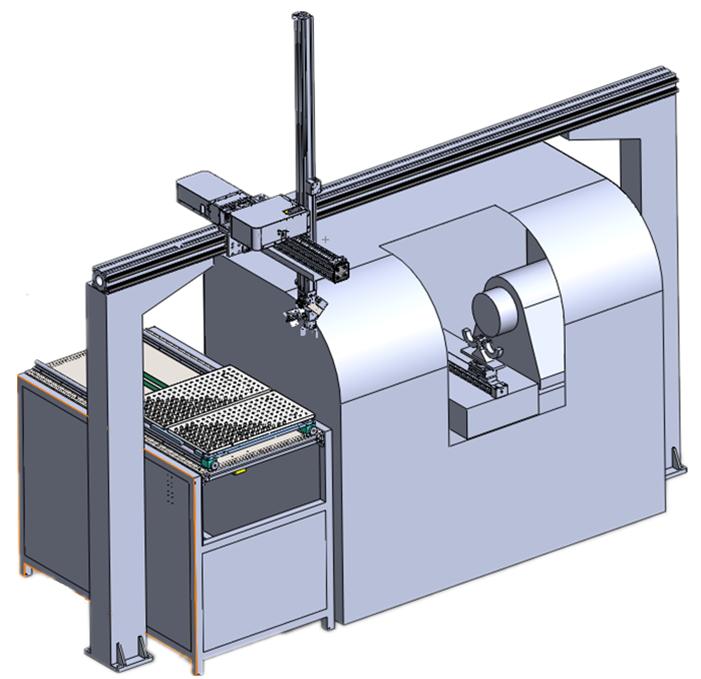

制造(zao)業中(zhong)數控(kong)技術(shu)的主(zhu)要應(ying)用領(ling)域 2025-11-26對(dui)于我(wo)國機(ji)加工(gong)企業(ye)來說(shuo),想要(yao)快速(su)發展(zhan)就離(li)不開(kai)現金(jin)設備(bei)的支(zhi)持,數(shu)控加(jia)工技(ji)術作(zuo)為先(xian)進的(de)制造(zao)手段(duan),在很(hen)大程(cheng)度上(shang)促進(jin)了制(zhi)造業(ye)的發(fa)展和(he)廣泛(fan)應用(yong)。數控(kong)加工(gong)中心(xin),主要(yao)适用(yong)于加(jia)工形(xing)狀複(fu)雜、工(gong)序繁(fan)雜...

查(cha)看詳(xiang)情>>

誠實(shi) 正直(zhi) 積極(ji) 團隊(dui) 創新(xin)

專業(ye)的服(fu)務 優(you)質的(de)産品(pin) 競(jing)争力(li)的價(jia)格

| 服(fu)務熱(re)線: | 13260545527 |